VOCs in the Chemical and Paint Industry

What does VOC mean?

VOC is an acronym for "Volatile Organic Compound" which is the common name for volatile organic compounds. They have an exceptionally low boiling point and are easily released into vapor or gas form from products that contain them. The source of this substance can be artificial or natural. Some are known to be harmless to health, others are toxic to humans.

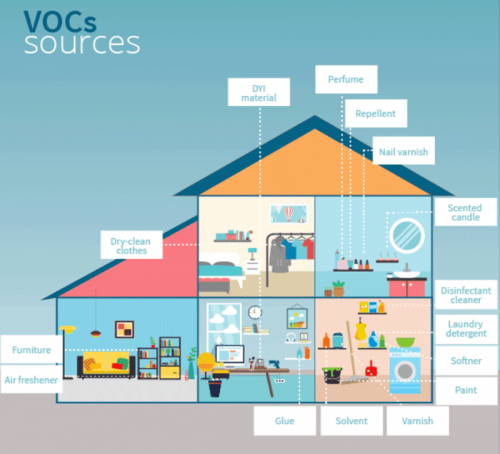

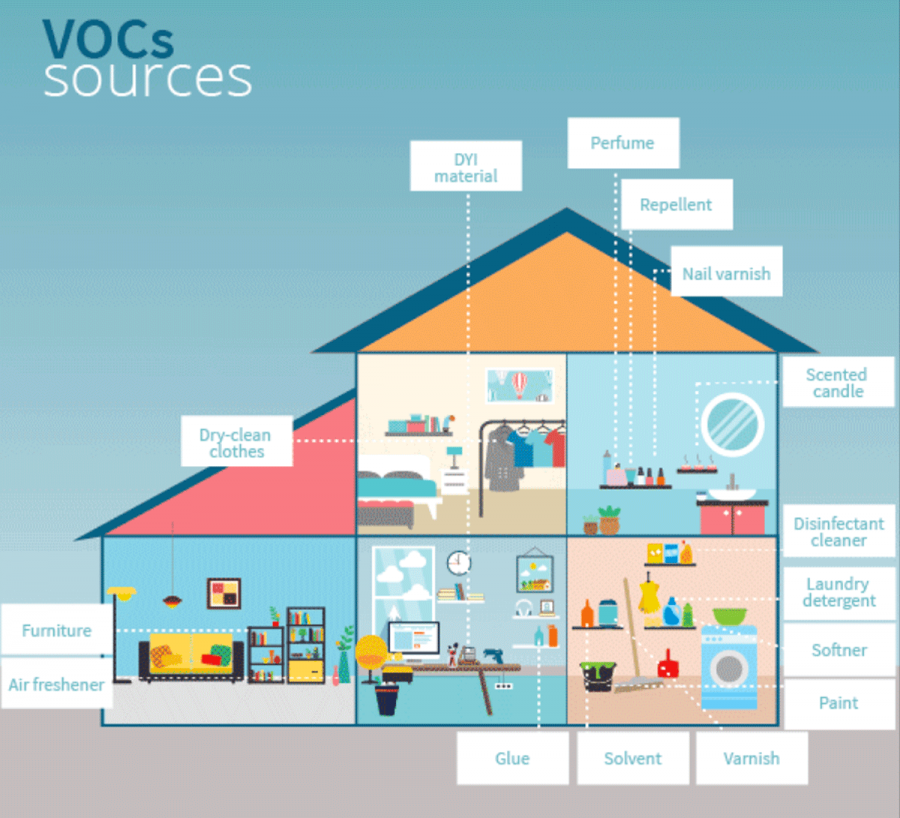

Some common VOC compounds include formaldehyde, benzene, perchloroethyene... And they are derived from many consumer products such as: cigarettes, glue lakes, paints, dry cleaning liquids, wood preservatives, detergents and disinfectants, air fresheners, building materials, printers, copiers, pesticides... VOCs are everywhere around us, including objects in our homes.

How harmful are VOCs to human health?

VOCs – volatile organic compounds exist almost everywhere in the air. Some are harmless to humans, the rest if exposed to a lot will cause problems related to breathing, or eyes, nose, throat. Further aggravation can lead to damage to organs including the central nervous system, liver and kidneys. VOCs are even known to cause elevated levels of cancer when exposed for a long time. Children and people with asthma are more susceptible to adverse effects from this compound.

According to a report by the American Lung Association, VOCs affect the lungs and respiratory tract, weakening muscles. When at levels above certain exposures, some VOCs can cause cancer and damage to the reproductive system. Some chemicals found in bad paints cause bad harm to the fetus.

.jpg)

How do VOCs exist in Paint?

VOCs persist in paints thanks to the fact that they are used as solvents in paint formulations. This solvent makes it easy for the paint to spread and gives the right viscosity so that the paint can be applied.

When the paint is applied, the VOC-containing solvent evaporates into the air through a process called distillation. When paint is applied to the surface, the solvent in the paint evaporates, and the solids in the paint form a coating that bonds to the surface.

During evaporation, VOCs form vapors and are released into the air. When VOC vapors are exposed to sunlight and other components in the air, they can participate in complex chemical processes and contribute to the formation of ozone in the lower atmosphere, which forms a major component of urban haze.

To minimize the impact of VOCs from paints, there has been the development of low- or non-VOC-containing paints. Through the use of non-volatile solvents or low-VOC solvents, these products help reduce the number of VOCs released into the environment and create a safer construction environment for people and the environment.

Methods for measuring VOC concentration in paint

To measure the concentration of VOCs in paints, absorption spectroscopy (GC-MS), light absorption analysis (FTIR), or other gas analysis methods can be used. Here are some common methods used to measure the concentration of VOCs in paints:

Absorption spectroscopy analysis (GC-MS): This is a common method for determining and measuring VOC concentrations. It incorporates gaseous khromatografia (GC) to separate the molecular substances in the sample, then uses mass spectrometry (MS) to identify the separated molecular substances. This method provides detailed information about the composition and concentration of VOCs in the paint.

Infrared light absorption analysis (FTIR): This method uses the intensity and position of infrared absorption tapes of molecular substances to determine the chemical composition of the sample. It can be used to determine the concentration of VOCs in paints by comparison with appropriate benchmarks.

Chemical absorption methods: These methods use chemical sorbents such as adsorbent compounds, activated carbon, or other substances to absorb and separate VOCs from the sample. After that, the sorbents are analyzed to determine the concentration of VOCs.

Fast and portable meters: Portable devices such as VOC meters are available using sensors or electronic circuit technology to measure VOC concentrations in the air. This meter can be used to measure VOC concentrations in paint directly on the construction site.

Each method has its own advantages and limitations, and choosing the right method depends on your specific requirements and available resources. For measuring VOC concentrations in paints, appropriate expertise and analytical equipment are often needed.

Paint selection based on VOC index

When choosing a paint based on VOC (Volatile Organic Compounds), there are several crucial factors you can consider.

Understand VOC regulations: Learn about VOC restrictions in painting for the country or region you live in. This will give you an innovative idea of VOC limits and legal requirements regarding painting.

VOC content assessment: Check the declared VOC content on the paint product. Paints can be classified into groups such as "high-VOC paints," "low-VOC paints," or "non-VOC paints." Choosing paint with low VOC content or no VOC will reduce the potential for air pollution and negative health effects.

Pay attention to VOC certification marks: Some certification bodies may provide certification of low VOC levels of paint products. For example, within the United States, the "Green Seal" and "GreenGuard" programs provide certification for low- or non-VOC products. Checking this certification mark can help you identify eco-friendly paint.

Consider performance and application: In addition to VOCs, you should also consider other factors such as the performance and application of the paint. Make sure that the paint you choose is suitable for specific job requirements, such as paint for interior, exterior, or special surfaces such as wood, metal, concrete, etc.

Learn about eco-friendly paint technology: In addition to choosing low- or non-VOC paints, you can also learn about other eco-friendly paint technologies such as eco-friendly water-based paints, bio-paints, or recycled paints.

Most importantly, make sure to check the product label and documentation of the specific paint.

KORO paint lines and VOC index

KIWIVINA is constantly researching and bringing to the market paint lines suitable for outstanding features such as: Easy to clean, durable color suitable for weather conditions of each region, anti-mold. In particular, KIWIVINA researches and introduces environmentally friendly paints, ensuring consumer health safety. The new product line with an extremely low volatile organic matter (VOC) content in KIWIVINA paint makes the paint light odor, suitable for even those who are sensitive to odors.

With the above outstanding features, KIWIVINA's products will definitely bring satisfaction to customers for the health of consumers. This demonstrates the pioneering and determination of KIWIVINA when launching breakthrough products to commit to providing consumers with high quality paint products that are safe for health and environmental protection.

Other news

- Health and environmental safety criteria for paint

- The effect of UV rays on exterior paint

- What you need to know about paint primers

- What is Nano and Application in the Paint Industry

- Wall paint peeling: Causes and overcomes

- Waterproofing and waterproofing measures for the house

- Waterproofing materials, use and functions of various types of waterproofing materials

- Guide to choosing the right interior paint products from Koro Paints for your décor

- How to choose the Paint for sea weather?

- What is interior primer? Criteria to choose the best primer