Waterproofing materials, use and functions of various types of waterproofing materials

Waterproofing material

Waterproofing materials are materials used to create a waterproofing layer on building surfaces to prevent natural factors such as air, water, climate, wind, and humidity from affecting the durability of a building.

These waterproofing materials have different properties and applications, depending on the type of construction and specific requirements. Typically, the choice of suitable waterproofing material depends on environmental conditions, building structures and construction techniques.

Types of waterproofing materials, uses and functions

Cement-based waterproofing material

Cement-based waterproofing is the easiest waterproofing method used in construction works. It is easy to apply by mixing cement-based waterproofing materials.

This method is often used in areas inside buildings and in high contact with water, such as toilets and bathrooms.

This method is usually used in areas exposed to high pressure such as pools and water tanks, and in humid places that are heavily exposed to water such as terraces, bathrooms, and basements. Cement-based waterproofing is usually fully resilient or semi-elastic but is not exposed to sunlight and weather conditions as it is used in areas such as toilets and bathrooms.

Cement-acrylic-based, two-component, fully elastic waterproofing material - CHIMEX 127, is a cement and acrylic-based two-component moisture and water insulation, which can be applied inside or outside on leak-resistant cement-based curtains and surface water. This is a good example of a cement-based waterproofing material by providing insulation.

Liquid repellent membrane material

Another commonly preferred method of waterproofing is liquid waterproofing materials. The liquid waterproofing film method is a thin coating, usually consisting of one coat of primer and two coatings applied by spraying, roller, or trowel. It provides more flexibility than cement-based waterproofing types. For this reason, it is used more intensely today.

The durability of a waterproof coating depends on the type of polymer that the manufacturer uses in the construction of liquid waterproofing. Liquid waterproofing membranes can be produced from sprayed liquid films consisting of polymerically modified asphalt. Separate acrylic, hybrid, or polyurethane liquid films for trowels, rollers or aerosols are also available from a variety of manufacturers.

Bitumen-SBS Rubber Based, Elastomeric Liquid Membrane – BLM 117 is a reliable option due to its superior protection against water and moisture.

Liquid bitumen film waterproofing material

Liquid bitumen coating is a type of coating used for waterproofing and flexible protective coating in accordance with its formula and degree of polymerization. Its flexibility and protection against water can be affected by the quality of the polymer layer as well as the fiber from which it is manufactured.

Liquid bitumen pavement is also called asphalt pavement. The most common applications of liquid coatings include areas under the screed. It is an excellent protective coating and waterproofing material, especially on surfaces such as concrete bases.

Liquid bitumen coatings are made of materials based on bitumen rubber and are used on all horizontal and vertical surfaces. It is preferred for external insulation of areas such as foundations, cellars, and basements, and for isolating enclosed areas in the interior of the house such as bathrooms, kitchens, and toilets.

Membrane waterproofing materials

Membrane waterproofing materials are one of the most popular waterproofing materials in the construction industry. This material is also highly preferred in roof insulation applications with ease of use and price/performance advantages. The membrane waterproofing cover is applied with the help of a torch flame source and therefore adheres very well to the surface. Building protective films against all possible liquids and sold in rolls can be produced in different thicknesses and models depending on the application area.

It is used under the coating in wet areas such as terraces and pitched roofs, balconies, flower beds, gardens, retaining walls and basements, sewage treatment plants, water tanks, ponds, swimming pools and decorative pools, kitchens, bathrooms, WC. It is also used in areas such as gardens and terraces in contact with the soil, thanks to its production of being resistant to plant roots. Therefore, it is used on the roofs of gardens and terraces of buildings in contact with the soil.

.jpg)

Polyurethane Liquid Film Waterproofing Material

The method of waterproofing polyurethane liquid films is used for flat roof areas and provides insulation of the roof against external factors. Polyurethane liquid film has high flexibility, designed not to be affected by external factors.

Before applying polyurethane films, it is necessary to consider that they are sensitive to moisture. For this reason, it is necessary to assess the moisture content of the concrete slab before application and to prevent peeling or loosening of the film.

Other news

- Health and environmental safety criteria for paint

- The effect of UV rays on exterior paint

- What you need to know about paint primers

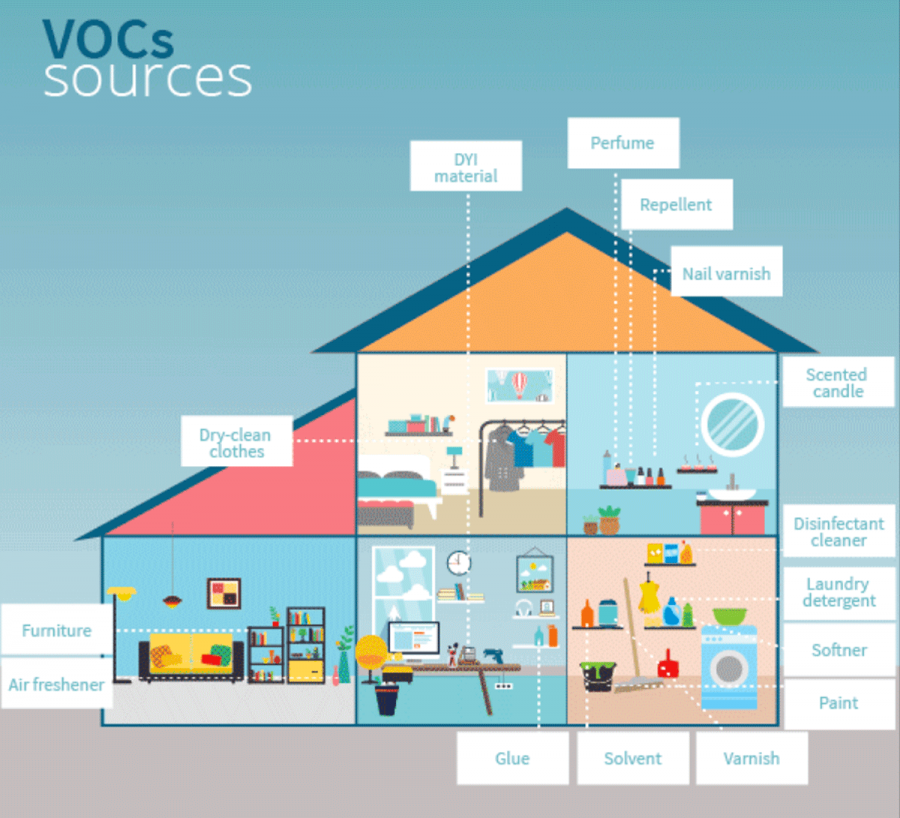

- VOCs in the Chemical and Paint Industry

- What is Nano and Application in the Paint Industry

- Wall paint peeling: Causes and overcomes

- Waterproofing and waterproofing measures for the house

- Guide to choosing the right interior paint products from Koro Paints for your décor

- How to choose the Paint for sea weather?

- What is interior primer? Criteria to choose the best primer